Rigid Flakes Pelletizing System

Rigid Flakes Pelletizing System

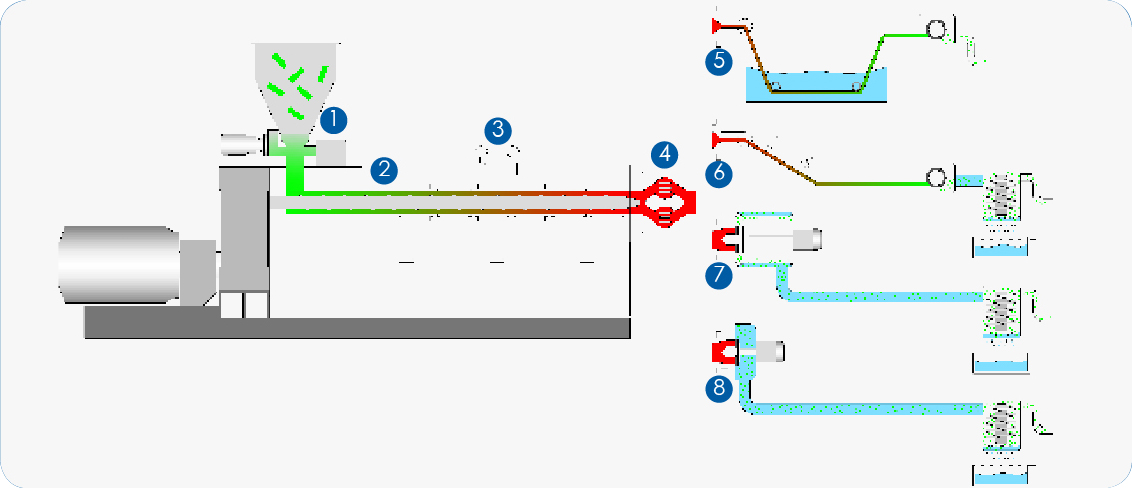

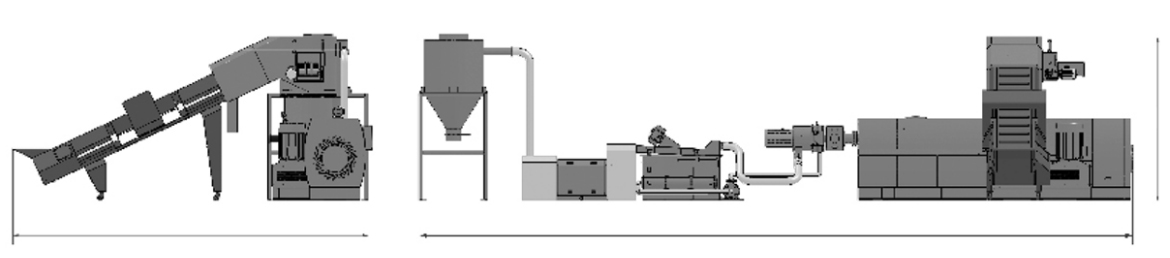

KSP series single screw extrusion and plletizing system combines quantitative feeding, high eficiency extruder,diferent types of filter and diferent types of plletizer by modular design.It provides best solution for PE, PP, PS, ABS, PET, PA and many other rigid plastic regrind recycling.

Dosing Feeder Unit |

Extrusion Unit |

Filtration Unit |

. Frequency control belt conveyor or screw conveyor are optional as loading device according to different material form.

| . High efficiency barrel and screw used for extruder with excellent plasticizing result and high output capacity. Adopt high wear resistant alloy material to ensure 1.5 times service life of normal one. . Force double vacuum degassing system to get rid of the low molecular, moisture and printing ink effectively, make sure high quality output pellets.

| . Plate type, pistion type, back flush type and automatic self-cleaning type filter, you have different choice according to impurity contents in material and your habit. |

Pelletizing Unit |

Intelligent Control Unit | |

. Water ring pelletizer, strand type pelletizer,automatic strand pelletizer and under water pelletizer, KiTech provides four different pelletizing solutions for you aiming at different MFI polymer will get different shape output pellets. | ·Thanks to Siemens PLC and HMI, KSP series machine provides high intelligent operation system which is easy to operate and save man power. . PLC intelligent control system available for remote diagnosis, control and monitoring to ensure that all user's systems can be updated and maintained and operated for a long term. . Weighing and metering system helps you monitor the output and energy consumption of production line in real time under different materials and production conditions. All data can be connected to ERP system for quantitative assessment. |

|

|

|

|

|

|

|

|

|

|

|

|

①Dosing Feeder ②Extruder ③Acuum Degassing ④Filter ⑤Strand Pelletizer ⑥Automatic Strand Pelletizer ⑦Water Ring Pelletizer ⑧Underwater Pelletizer

Ability |

Stability |

Thanks to innovative pelletizing technology and proprietary process. KiTech dedicated tosupplying you intelligent recycling pelletizing system with superior quality Which have highproductivity could get high property output pellets. | KSP pelletizing system is available for 24 hours working non-stop operation. Optimized design and top brond components to each unit. Which could minimize the downtime ratioand save the maintenance time. This ensures the maximum availabiity and highest productivity for user. |

Efficiency |

Modularity |

KSP pelletizirtg system is designed in all details for efficiency improving. The modular design could simplify the planning and accelerote the Implementation. The system havevery low consumption values for electricity, water and labor. The operating costs and mointerKince costs are absolutely reduced. Consistently the lowest investment costs andhighest value aeation. | KSP pelletizing system is a flexible modular system. The process required by any customer for different application could be combined freely. This design reduces planning construction and assembly time effectively, And it's possible to adjust thesystem regardto technological modification and market changing. This makes the investment futureproofing. |

Control |

Service |

Automatic control of KSP pelletizing system reduces the labor operation, makes the whole system easier and more reliable to control, the remotes monitoring and maintenance areavailable for different production line The intelligent control has display for operating data.it also collect the data of the consumption and the capacity from production lines Whichensures the connection between the enterprises and the Internet will improve the effciency of enterprise management. | KSP pelletizing system is a flexible and customer-oriented recycling solution. All the |

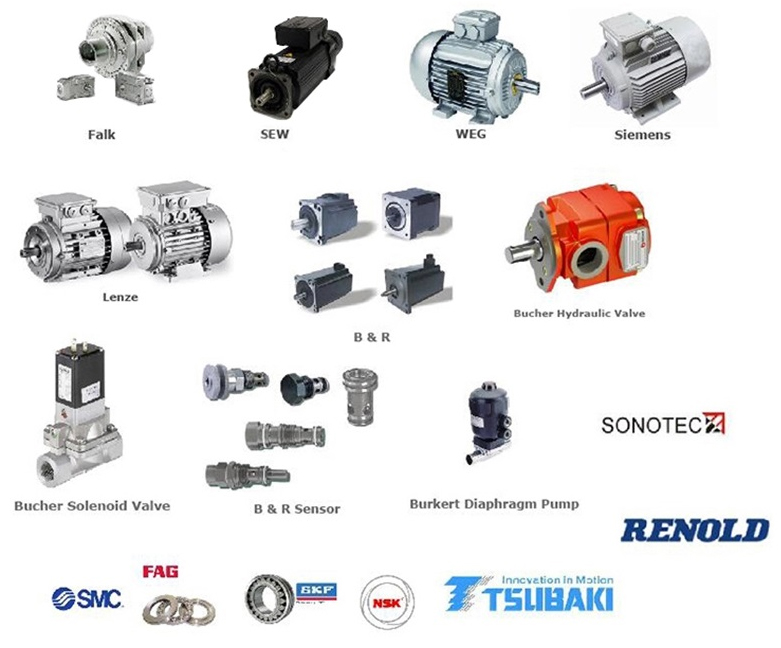

Electrical Parts

Technical Data

| TYPE | KSP100 | KSP120 | KSP150 | KSP180 | KSP200 | |

| Capactity[kg/h] | 300-380 | 400-450 | 600-750 | 800-950 | 1000-1200 | |

| Energy Consumption[kWh/kg] | 0.2-0.30 | 0.2-0.30 | 0.2-0.30 | 0.2-0.30 | 0.2-0.30 | |

| A/Length[mm] | 12,500 | 13,800 | 14,900 | 15,200 | 16,500 | |

| B/Width[mm] | 2,500 | 2,500 | 2,500 | 3,300 | 3,500 | |

| C/Height[mm] | 3,750 | 3,980 | 4,250 | 4,460 | 4,850 | |

| Extruder | Screw Diameter[mm] | 25-35 | 25-35 | 25-35 | 25-35 | 25-35 |

| Motor Power(kW) | 90-110 | 132-160 | 160-200 | 250-315 | 315-355 | |

| Aacuum Exhaust | 1-2Area | 1-2Area | 1-2Area | 1-2Area | 1-2Area | |

| Filter[options] | Two Position Plate Type | ● | ● | ● | ● | ● |

| Two Position Piston Type | ○ | ○ | ○ | ○ | ○ | |

| Back Flush Piston Type | ○ | ○ | ○ | ○ | ○ | |

| Automatic Self-Cleaning Type | ○ | ○ | ○ | ○ | ○ | |

2nd Extruder [options] | Screw Dimeter & L/D | Φ120&8-12 | Φ150&8-12 | Φ150&8-12 | Φ180&8-12 | Φ200&8-12 |

| Motor Power(kw) | 37-45 | 45-55 | 55-75 | 75-90 | 90-110 | |

| Aacuum Exhaust | 0-1Area | 0-1Area | 0-1Area | 0-1Area | 0-1Area | |

Downstream [options] | Water Ring Pelletizer | ● | ● | ● | ● | ● |

| Strand Pelletizer | ○ | ○ | ○ | ○ | ○ | |

| Automatic Strand Pelletizer | ○ | ○ | ○ | ○ | ○ | |

| Underwater Pelletizer | ○ | ○ | ○ | ○ | ○ | |

●standard ○alternative